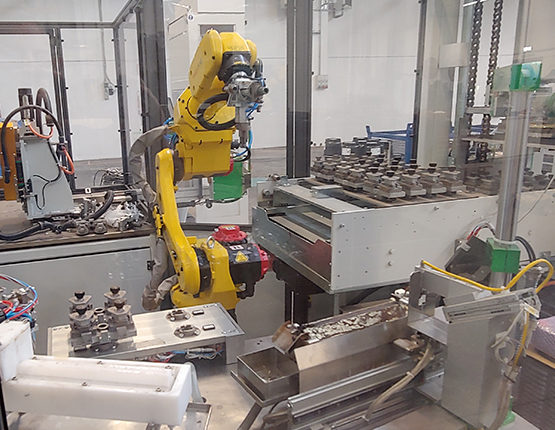

Robotics and automation for the metalworking and mechanical engineering industry

An integral part of our business is dedicated to robotics and industrial automation in the metalworking and mechanical engineering sector. By this, we mean in particular the automotive industry, i.e. construction technologies for motor vehicles and related components. Cars, trucks, vans, HGVs and work vehicles: ADBrobot can provide its customers with cutting-edge robotic automation solutions to integrate into their production lines, including 24-hour non-stop production cycles. Our robots, suitably programmed, perform any type of repetitive and wearing operation, in compliance with the safety requirements and quality standards required by the automotive and metalworking sector in general.

ADBrobot’s strength is continuous updating of the systems used and the programming software chosen, a fundamental approach to keep up with the times and always guarantee results that meet expectations, even in the most critical situations. Turning to us means relying on a specialised partner, capable of analysing the client’s real needs and transforming simple ideas into effective and modern automation proposals. Thanks to the synergy of a motivated and competent team of professionals, technicians and engineers, ADBrobot now offers its range of services all over the world, to a cross-sector clientele seeking reliable and flexible solutions in the world of robotics.